ibg Article for QZ Magazine “Optical Reflection and Eddy Current Combined”

12/01/2023

Robotic Surface Inspection with the Optical Reflection Sensor by ibg

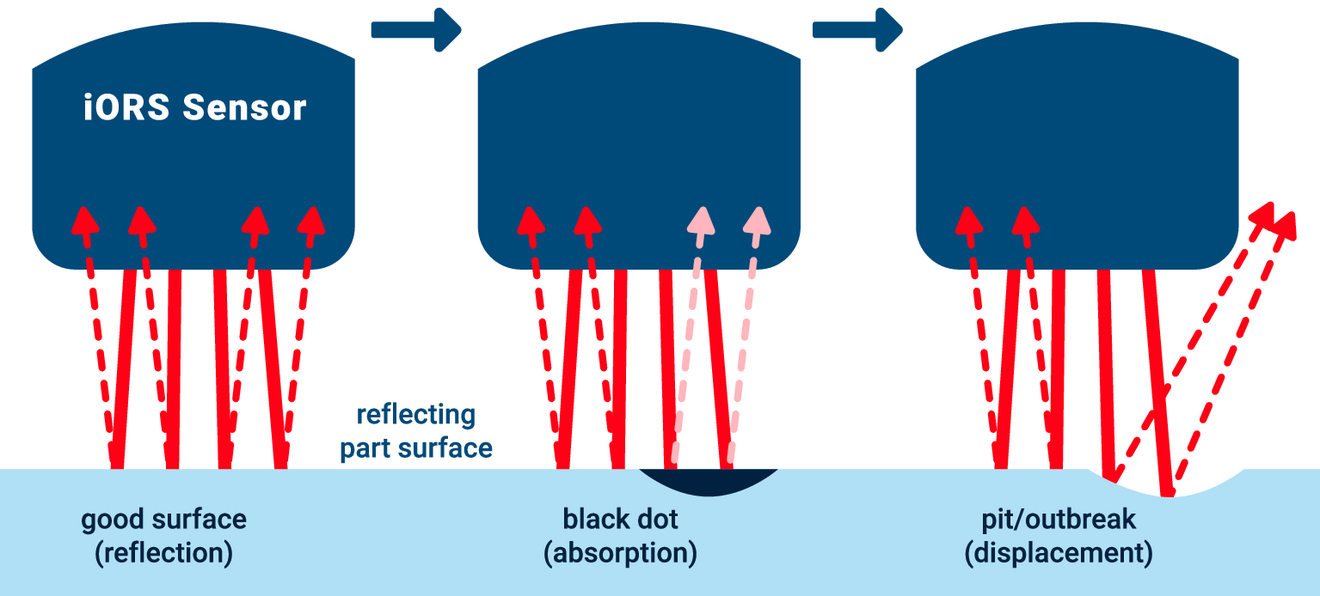

The iORS sensor introduces a new, fast, and easily automatable approach to detecting defects on high-quality steel components such as rings, rollers, and balls. It employs a second physical principle, optical reflection, in addition to the established eddy current technology, enhancing accuracy and precision.

Efficient Surface Inspection: Identifying and Addressing Flaws in Steel Components

One of the main tasks and challenges in surface inspection is identifying flaws such as so-called black spots (unpolished areas), breakouts, pores, or relevant contaminations that can affect the lifespan and reliability of steel components.

In Combination with Other Probes

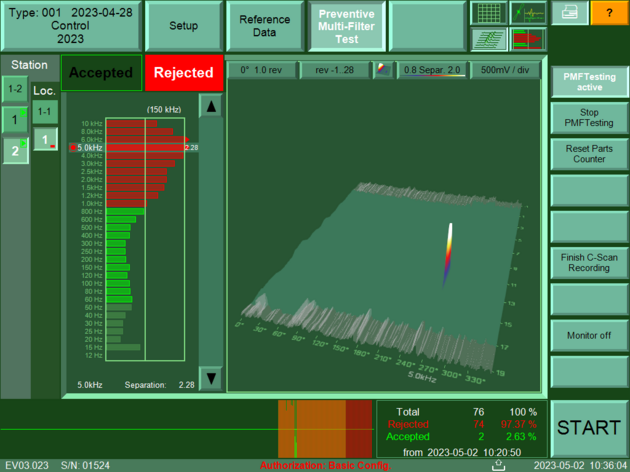

The combination with eddyvisor allows component manufacturers to benefit from the advantages of simultaneous use of optical reflection scanning and eddy current crack detection, optimizing throughput performance and inspection times while conserving investment budgets. This synergistic integration not only streamlines the inspection process but also significantly reduces the likelihood of overlooking potential defects. Manufacturers can achieve a dual benefit of heightened precision and cost-effectiveness, making the combination of iORS and eddyvisor a strategic investment for robust quality control in steel component production.

A Robot for More Efficient Deployment

The suitable companion for the new generation of sensors for one hundred percent inline quality control is the inspection system concept, Eddyrobot. It operates autonomously integrated into production lines, reducing the influence of the human factor and ensuring the consistency and accuracy of inspections.

Versatile Inspection Precision: Eddyrobot Masters Subsurface Defects with ibg Technology

The eddyrobot's prowess in seamlessly integrating the ibg Subsurface Eddy Current probe and the Optical Reflection Sensor (iORS) underscores its adaptability across diverse inspection scenarios. This comprehensive solution not only enhances defect detection efficiency but also solidifies the eddyrobot's position as a cutting-edge tool for precision-driven quality control in steel component manufacturing.

Revolutionizing NDT: Eddyrobot and iORS Duo Elevates Precision and Efficiency in Automated Quality Control

The eddyrobot and iORS together mark a significant leap in non-destructive testing. The eddyrobot brings precision and automation, ensuring the safety of critical components, while iORS offers high precision for steel surface inspection without the complexity of image processing systems. Their combined use with Eddyvisor crack detection sensors enhances efficiency in automated quality control processes.

An article by Wolfgang Korpus on "Optical reflection and eddy currents combined" has been published in QZ magazine.

You can read it online here on the specialized portal in German:

www.qz-online.de

Or read here the full article in English:

Contact ibg today to learn how these solutions can benefit your production processes.