eddyrobot: Revolutionizing Sample Testing, Redefining Precision and Efficiency

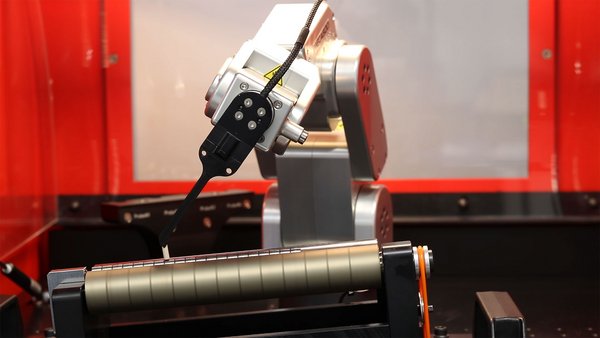

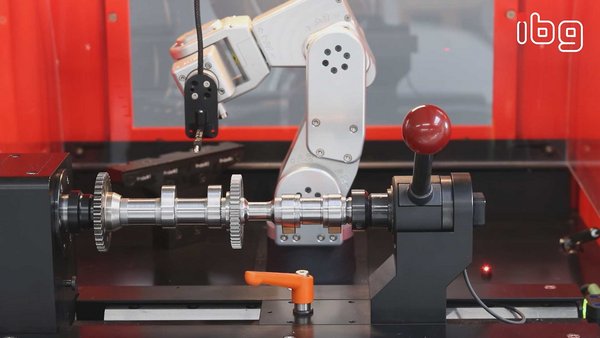

Welcome to the future of sample testing with ibg eddyrobot. Our modular unit is specifically designed for semi-automatic eddy current crack and grinder burn detection and also for surface inspection by ibg's Optical Reflection Technology ORS on a wide range of part geometries. With easily interchangeable drive units, this innovative technology offers a new level of versatility and efficiency in quality control.

Discover Versatile Applications and Features of ibg eddyrobot for Precision Testing

Efficient and precise quality control is paramount in today's manufacturing landscape. To meet the ever-growing demand for streamlined inspection processes, ibg presents the innovative eddyrobot. This modular unit revolutionizes sample testing, offering a range of applications and benefits that enhance the quality assurance process across industries. We will explore the diverse applications of the ibg eddyrobot, from production line resets to sampling inspections and Nital etch replacements. We'll also delve into its user-friendly design, ideal installation locations, and key features that make it a game-changing addition to your quality control arsenal.

Use the ibg eddyrobot to inspect the first parts after resetting a production line, ensuring the initial quality of your components.

Perform sampling inspections during ongoing production runs to maintain consistent quality standards.

Add the power of eddy current testing and replace traditional nital etch sample testing. eddyrobot provides a more efficient and environmentally friendly alternative.

Ibg eddyrobot is designed for ease of use by production workers. Its intuitive interface and straightforward operation make it a valuable addition to your quality control process.

Consider positioning the eddyrobot at your production line or in an offline self-service inspection area within the production hall. It complements instruments for roundness and surface roughness measurements, making it also a convenient addition to quality laboratories. Additionally, test service providers can expand their range of potential orders with the eddyrobot.

Discover the Advanced Key Features of ibg eddyrobot: Precision, Efficiency, and Safety in Sample Testing

- Testing Approaches:manual loading / automatic testing;

- ibg Test Instrument eddyvisor C:Equipped with a differential crack test probe, ensuring precise and reliable testing.

- High-Precision 6-Axis Robot: Achieve repeatability within ±5 microns for consistent results.

- Selection of exchangeable drive units for a wide range of part families: including roller, rings, shaft, wheel hub components, freeform;

- Flexible Probe Station: Stores up to four ET probes, automatic probe change by the robot (magnetic tool holder) based on part-type specific programming.

- Beckhoff PLC-PC and 15.6" Touch Screen: Advanced control and user interface for seamless operation.

- Optional QR-Code Reader: Streamline production order management for increased efficiency.

- Safety Features: Includes an electro-mechanical lock and emergency stop for operator safety.

- Mobility: Move the unit effortlessly with 100 mm rubber wheels (two lockable), a large handle, and rugged corner protection. It easily fits through standard doors (1,213 x 804 x 1,856 mm l x w x h).

Unlock Precision, Efficiency, and Sustainability with ibg eddyrobot - Elevate Your Quality Control Today

ibg eddyrobot represents a significant advancement in sample testing technology, offering precision, efficiency, and environmental responsibility. Elevate your quality control processes with this cutting-edge solution. Contact us today to learn more and explore the possibilities with ibg eddyrobot.

Contact Us