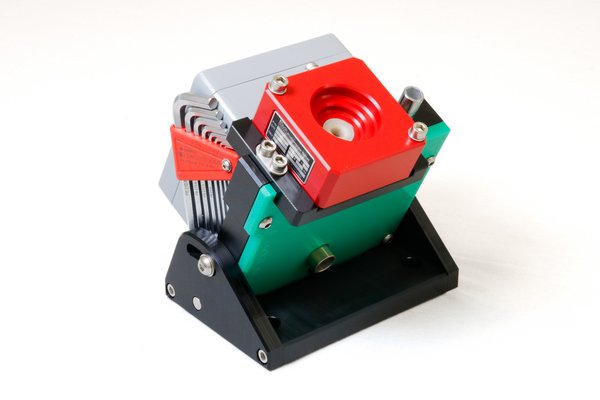

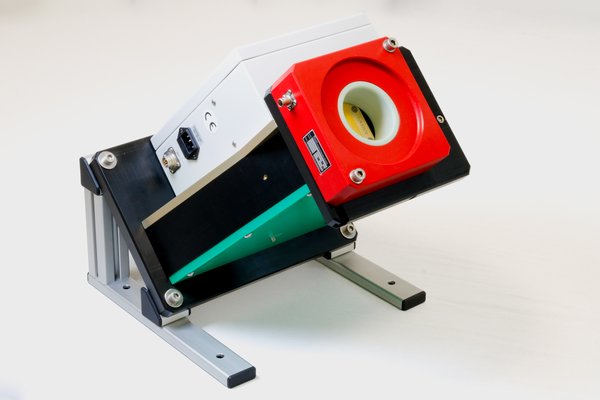

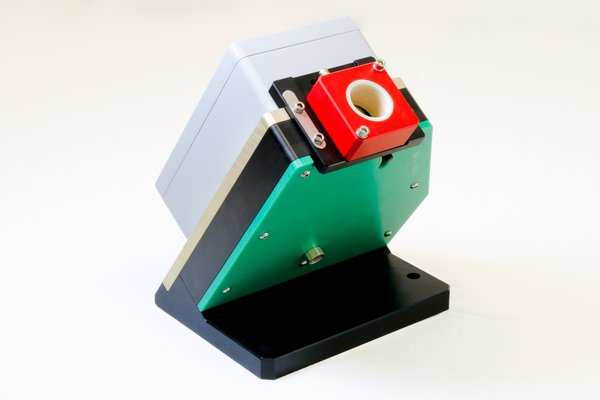

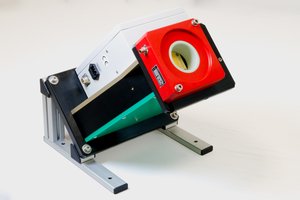

Explore the ibg UNISort Sorting Gates for Universal, Fast, and Cost-Saving 100% Structure Testing

Manufacturers and refiners of components who have to handle small and medium batches know the problems: automation is not thinkable due to high investment for such quantities, and manual handling is too cost-intensive due to labor costs. A compromise must be found. If you need a 100% material test of your part the ibg sorting devices UNISort 10 HD, 25 HD, 40 HD, and 63 HD could be your solution. Combined with one of ibg’s test instruments eddyvisor S, eddyliner S, or eddyguard S, and the appropriate coils, this semi-automatic test “out of the box” can realize cycle times of approx. 1 part/sec. with one test worker. Test parts (diameter 1-60mm) are fed manually in the coil, testing is done automatically as well as sorting to the OK or NG chute.

ibg UNISort Sorting Gates: Versatile, Rapid Setup, and Expandable for Growing Demands

The equipment is ready to work within minutes and can be changed to other part types very quickly. Best suitable for testing smaller and medium batches it is often used for “first responder jobs” as it is easily transported. Adding a suitable feeding and escapement enables it to be used in automatic mode when demand increases. The UNISort is controlled by the ibg eddy current test instruments, no additional control is needed. The power supply for UNISort 10 / 25 / 40 HD is taken from the ibg test instrument. The UNISort 63 HD has its own power supply.

Durable Design for Demanding Environments and Customization Options

The UNISort works at the same time as a fixture for the test coil and as a sorting gate. The sorting flap is monitored by a proximity switch. In combination with the coil monitoring of ibg eddy current structure test instruments malfunctions of the test equipment are recognized.

ibg sorting devices are designed for rough applications in industrial environments. Wear-resistant ceramic components are used among others in order to deal with challenging conditions in foundries and heat treatment shops ensuring a long lifetime of our products. If something is worn after years you can rely on a quick repair and availability of spare parts.

The standard scope of supply offers ibg UNISort devices in four different sizes (up to 10mm, 25mm, 40mm, and 63mm part diameters) which are available for quick delivery. Customized devices for special geometries or larger test parts are available on request.

The advantages of ibg UNISort sorting gates at a glance:

- large testable parts range

- for immediate and universal use

- works with all ibg structure test instruments

- long lifetime due to high-quality components and easy exchange of worn parts

- non-stop operation

- easy integration in automatic test systems

- sorting gate monitoring

Overview of Information about ibg UNISort Sorting Gates

| UNISort 10 HD | UNISort 25 HD | UNISort 40 HD | UNISort 63 HD | |

|---|---|---|---|---|

| Weight of the Unisort | 3 kg | 4 kg | 8 kg | 13 kg |

| Power Supply | 24 VDC (10 - 40 HD: ibg instrument, 63 HD: external supply) | 24 VDC (10 - 40 HD: ibg instrument, 63 HD: external supply) | 24 VDC (10 - 40 HD: ibg instrument, 63 HD: external supply) | 24 VDC (10 - 40 HD: ibg instrument, 63 HD: external supply) |

| Ambient temperature | - 10 to + 60°C | - 10 to + 60°C | - 10 to + 60°C | - 10 to + 60°C |

| Protection class | IP 55 | IP 55 | IP 55 | IP 55 |

| Mmax. part temperature | 50°C | 50°C | 50°C | 50°C |

Contact Us