ibg Structure Test Coils & Probes: Precision Sensors for Every Testing Challenge

Versatile Standard and Custom Sensors for Precision Testing

Our wide range of standard sensors includes encircling coils, rectangular coils, fork coils, inner diameter coils, flat coils, and probes. Customized products for special test tasks are provided by our in-house design and manufacturing team. ibg coils stand out due to the highest test sensitivity and temperature stability. Furthermore, they offer maximum of investment security as they may be operated with all ibg structure test instruments. So you can replace an old ibg test instrument with a new generation instrument, and the coils can still be used. Selecting the right coil design for your application is always based on one main question: how to approach the area of a part that contains most of the relevant microstructure and its potential deviation. Therefore ibg offers a variety of designs and geometries to keep up with your parts.

Precision Testing with Encircling Coils: Ideal for Heat Treatment Evaluation

Encircling coils are generally used when testing for correct heat treatment with ibg’s Preventive Multi-Frequency Technology. Diameters from 5 mm up to 300 mm are available as standard (larger coils on request), and our experience shows that 90% of all applications can be successfully tested within that range. Typical applications include testing for correct hardness, case depth, material mix, alloy, and microstructure – just to mention a few examples. Special applications sometimes require special coils and sensors designed for a certain test task. Our in-house coil design & manufacturing team, which produces all ibg probes and coils, specializes in exceptions and is able to manufacture coils for each field of application. It may be sensible to use rectangular coils when testing bearing rings, for example, in order to penetrate the material with the magnetic field. Testing of con-rods is also an application for rectangular coils.

Shielded Coils for Precise Detection of Induction Hardening Variations

When differences in hardening zone position in the induction hardening process (pattern shift, run out) need to be detected, special shielded coils can be manufactured. The magnetic field is influenced in a way that only the critical area is tested. Influences from surrounding areas are significantly reduced by that. Even the smallest deviations in the position of only 0.5 mm can be reliably detected depending on part geometry and material. Our shielded coils pinpoint hardening zone position differences, detecting deviations as small as 0.5 mm based on part characteristics.

Fork Coils and ID Coils: Tailored Solutions for Specialized Testing Needs

Precision Testing of Inner Diameters and Boreholes with Tailor-Made ID Coils

Typical encircling coils where test parts are placed inside do not reach areas on the inner diameter or in boreholes in most cases. The magnetic field of these coils cannot penetrate the material from outside sufficiently for a reliable test. Typical examples are races in a hub or the inside of bells of a CV joint or tripod. ibg has developed ID coils in order to solve such applications with appropriate sensitivity and reliability. The coils are tailor-made for a certain application, and the areas to be tested inside the test part are directly reached. ID coils are supplied in a diameter range from 5mm on. Low-wear versions in stainless steel are also available to guarantee a long lifetime for applications with a high number of parts and short cycle times.

Ensuring the Reliability of Your Smallest Components

The smallest parts are quite often responsible for the breakdown of an entire component. Geometrically unimposing, not even very precisely manufactured, and a few millimeters in length or height. But if their heat treatment is not correct, they can cause malfunction of an entire component like an injection pump or a steering. A 100% test of such critical components for correct heat treatment, as well as a safe internal material process flow with locked containers avoids, such errors. The coil manufacturing at ibg is specialized in testing small and very small components and may offer customized solutions to test such minis. Most often encircling coils are used, round or rectangular, which are designed especially for your test parts. In combination with the Preventive Multi-Frequency Technology well proven for such product groups and the Simultaneous Harmonic Analysis in all ibg structure test instruments, we offer the optimum solution for your difficult task.

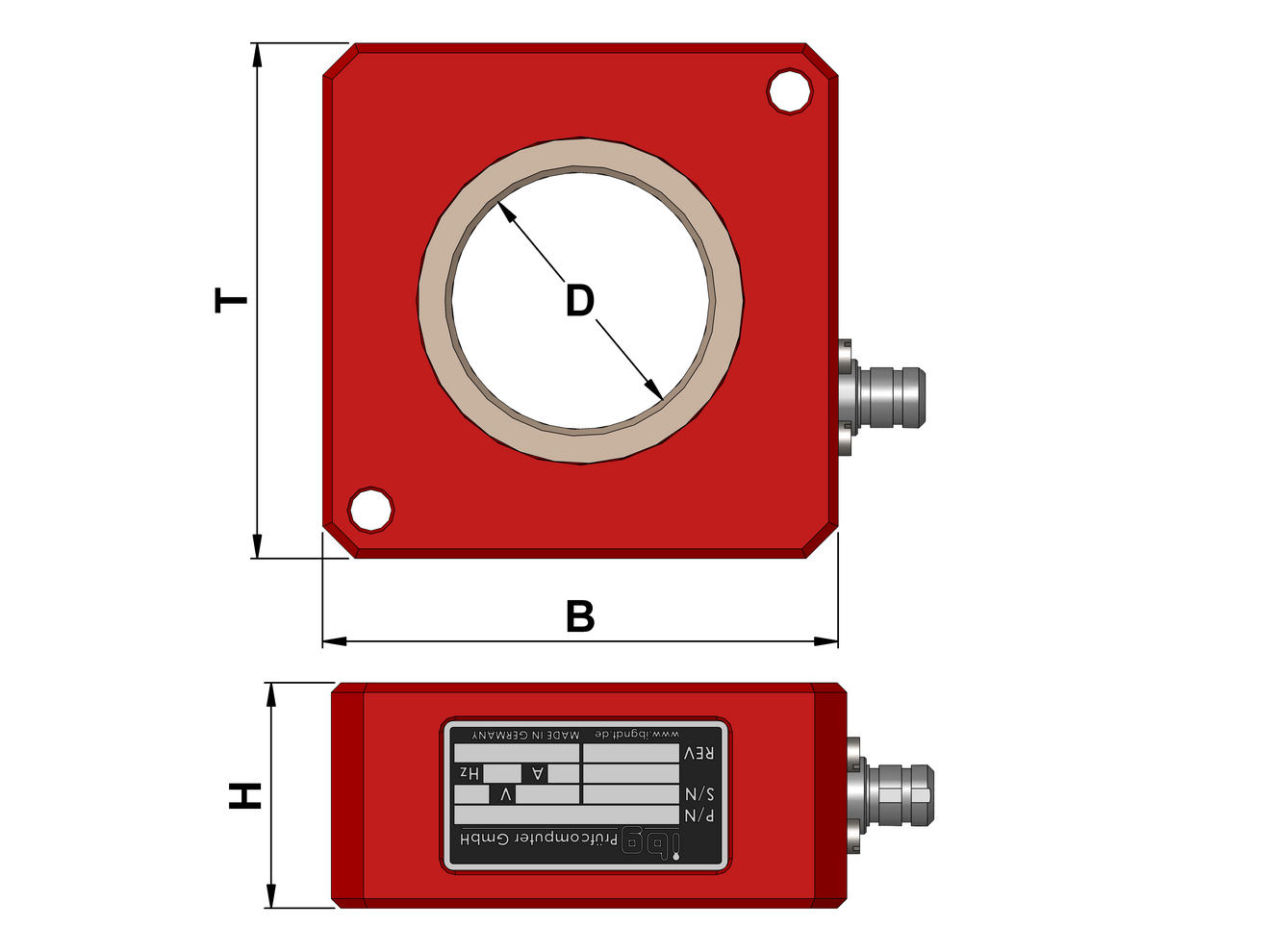

Encircling round coils (standard range)

| Size | Dimensions b [mm] x t [mm] x h [mm] | Inner diameter [mm] |

|---|---|---|

| 1 | 80 x 80 x 35 | 10, 16, 25, 40 |

| 2 | 150 x 150 x 50 | 50, 63, 80, 100, 125 |

| 3 | 250 x 250 x 50 | 160, 180, 200 |

| 4 | 380 x 380 x 50 | 250, 300 |

Other inner diameters can be made to measure

Available frequency ranges: 25 Hz – 25 kHz (standard)/ 5 Hz – 5 kHz/ 100 Hz – 100 kHz

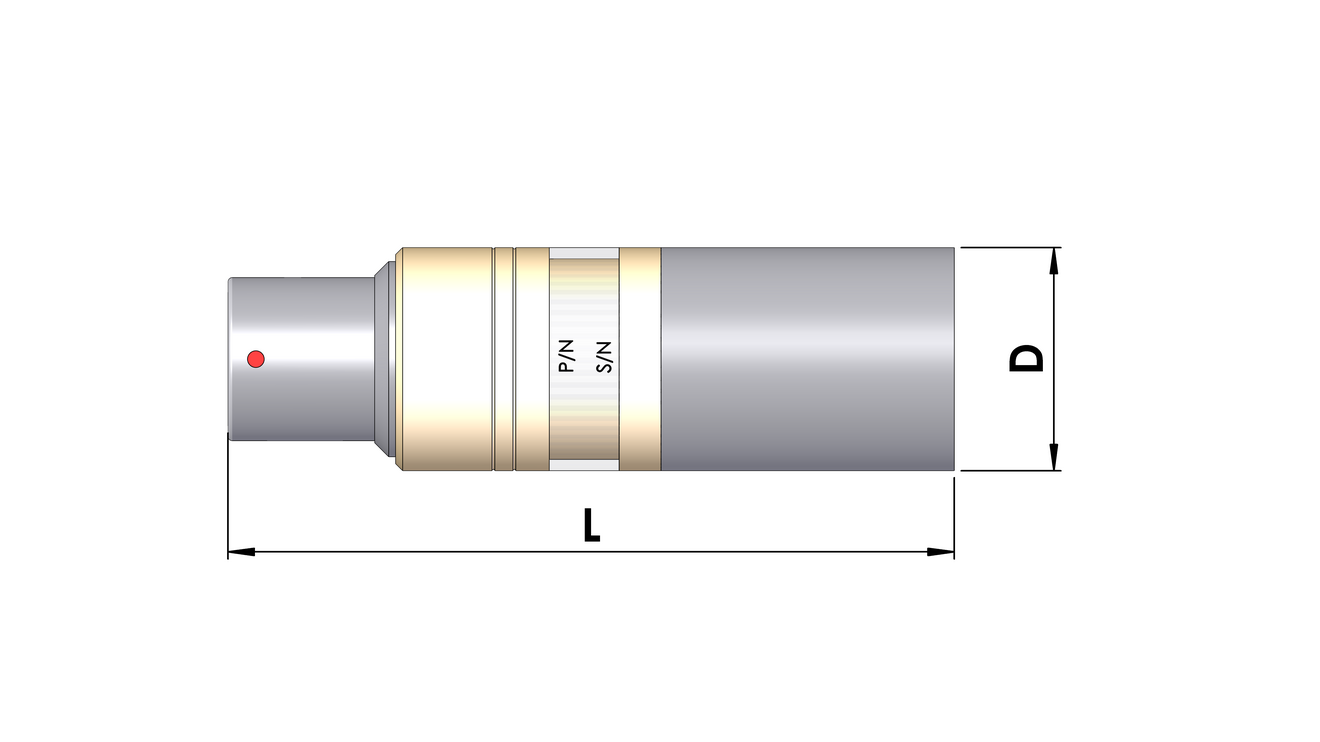

Structure test probes (standard range)

| Diameter d [mm] | Lenght l [mm] | Frequency range |

|---|---|---|

| 10 | 46 | 2,5 kHz – 250 kHz |

| 16 | 47 | 250 Hz – 25 kHz |

| 25 | 51 | 25 Hz – 2,5 kHz |

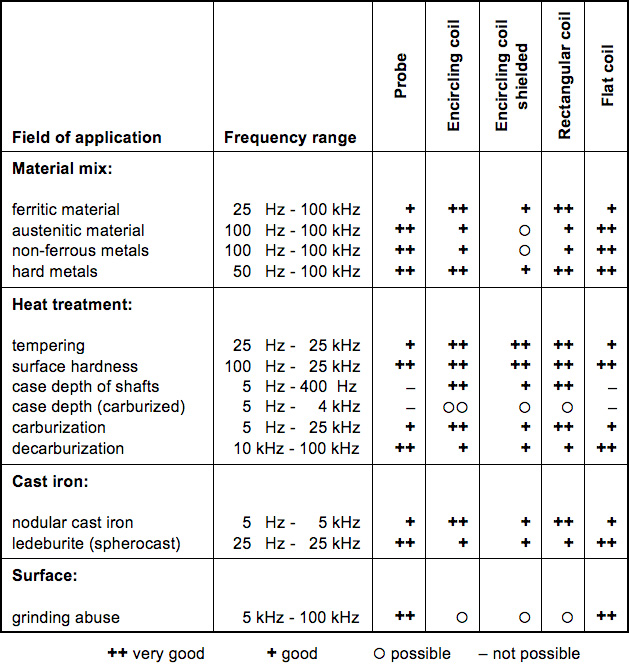

Recommended coil technology for various applications

Contact Us